Concevez des semelles sur mesure pour vos patients

PodoProductions est une société belge qui propose un service d’usinage de semelles plantaires sur mesure aux podologues et podo-orthésistes.

Comment ça fonctionne ?

Découvrez toutes les étapes de conception de nos produits PodoProductions.

Découvrez nos services

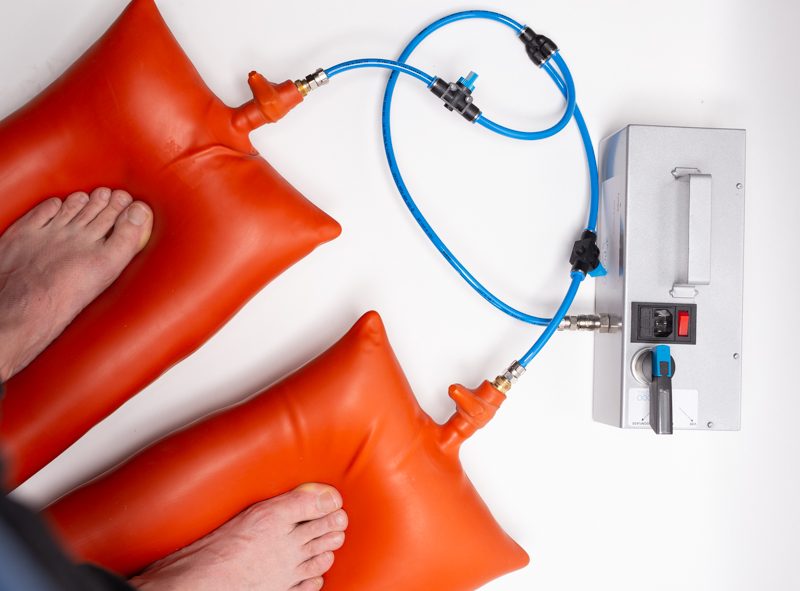

Équipez-vous avec un matériel performant et à la pointe de la technologie !

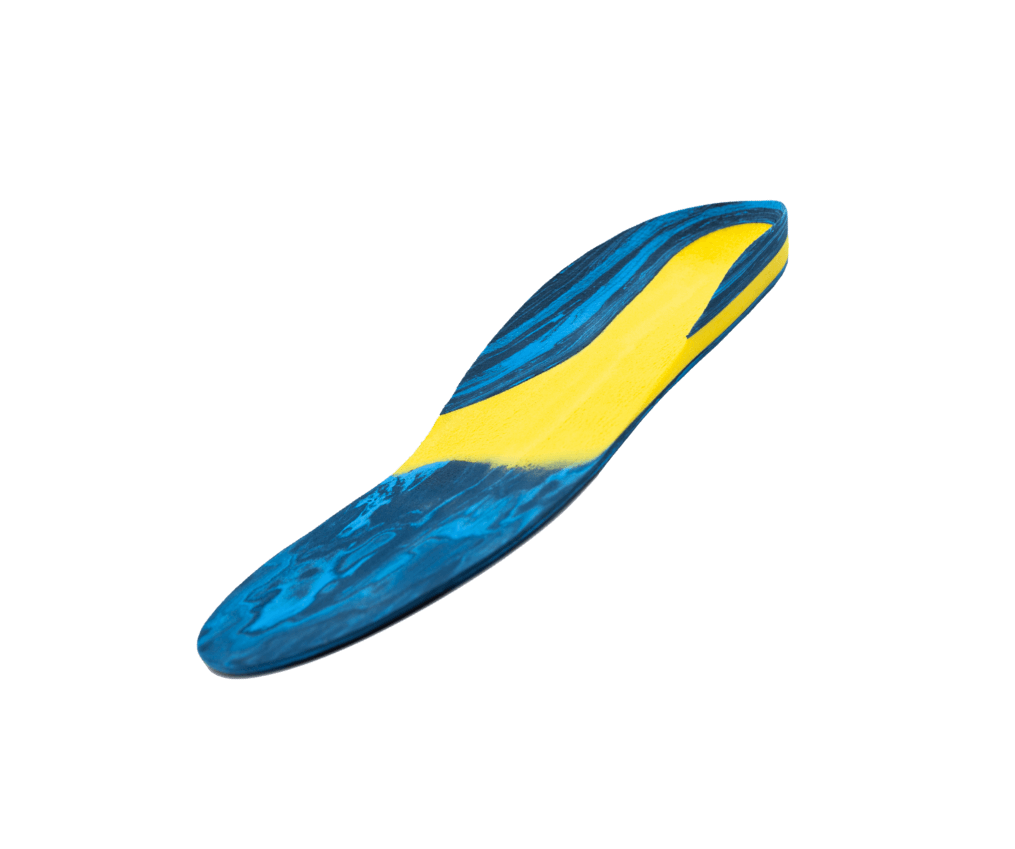

Semelles

Nous usinons des semelles brutes sans finitions et sans recouvrement. Les semelles peuvent être finies de plusieurs façons différentes pour des résultats très variées.

SemellesNous vous accompagnons au quotidien !

Notre équipe vous offre tous les services nécessaires à votre bon fonctionnement.

Démarrez dès maintenant

Et bénéficiez de nos offres exclusives en quelques jours seulement…

Ils nous font déja confiance !

Venez découvrir les témoignages de nos clients…

Podologue en région Centre-Val de Loire

J’utilise les services de la société PodoProductions depuis bientôt 10 ans: Optimisation de mon temps de travail, valorisation de ma communication auprès des différents praticiens de santé et de mes patients, valeur ajoutée incontestée au développement de ma patientèle…

Les orthèses plantaires 3D font maintenant partie de mon quotidien et ont largement contribué à mon bien-être professionnel.

Podologue en région Bourgogne-Franche-Comté

La technologie Podoproductions permet, en plus du gain de temps et de place en atelier, de fidéliser la patientèle très demandeuse de cette technique. Semelles toujours livrées à temps et équipe réactive, à notre écoute autant en formation qu'en résolution des problèmes. Huit ans de travail ensemble sans souci, c'est appréciable.

Podologue en région Bourgogne-Franche-Comté

Je suis adepte du système Podoproductions depuis 2014. Celui-ci révolutionne véritablement la réalisation des semelles orthopédiques. Par rapport au thermoformage, le procédé permet d’obtenir des semelles plus précises, plus efficaces et moins encombrantes. Totale satisfaction !

Démarrez dès maintenant

Et bénéficiez de nos offres exclusives en quelques jours seulement...

C'est parti !